Q&A With Angus McRaild, Decadent Drinks

An Interview With The Man Behind Whisky Sponge And Co-Founder Of Decadent Drinks

By Kurt Maitland

(Credit: Kurt Maitland)

If you are a big fan of Scotch, you have probably heard of Angus MacRaild. It could have been via his satirical blog, Whisky Sponge (“the Onion” of the whisky world) or his independent bottling operation, Decadent Drinks (both highly recommended). Or perhaps you’ve seen him at London’s Whisky Show with a lineup of vintage bottles that are an education in and of themselves. Or maybe you’ve seen his reviews and commentary on Serge Valentin’s Whisky Fun website. Regardless, for as long as I’ve known him he has been a man you should keep an eye on..

While researching an article for Distiller about how distilling practices from decades long gone might have been better, he and I had quite the conversation. Much of it focused on one of the most eagerly awaited distillery openings in Scotland, Kythe.

Angus and his partners in this worthy endeavor, Jonny McMillan and Aaron Chan (all impressive whisky personalities in their own right), are trying to bring back the flavors that dominated the whiskies of decades past and Kythe will be the way they resurrect them.

KM: So let’s talk old styles of whiskies, both in the States and Scotland.

AM: I think the whole “Old Style” whiskey thing can mean something quite different in America, and it’s a totally different world. Whenever I’m going around asking about bottlings of American whiskey, I’m always speaking to producers. One of the first things I’m always asking is “What’s your cask filling strength?” Because I essentially just want some of those old school, fruity bourbon flavors that are hard to find.

KM: Speaking of those “old school flavors,” I know that with Kythe you will be trying to reverse engineer the flavor/styles of the old whiskeys you love.

AM: I want these flavors be more prominent and available versus having to go and hunt down dusties (vintage bottles). There’s no good reason why this stuff isn’t on a shelf. It’s not like it’s never been made before. We do know how to make it. It’s just that the big brands don’t want to because what was commonplace back then has become very expensive to do now.

That’s the catch. So you need a different business model to try to create the sort of liquid and product, and level of quality that we want to do. It’s expensive to make that. It flies in the face of the standard business plans and objectives of modern major companies. So for us, you have to start from scratch.

KM: So how did you go about it?

Angus MacRaild: We’re not taking an existing distillery and retrofitting it. We’re not buying into an existing distillery that still had aspects of its architecture and equipment from the 50s or anything like that. We had to start from scratch, which was cool and ended up being the most cost effective way to do it in some respects.

It required a different sort of business plan – here’s how you make money, and it means you probably have to be a bit more expensive, you have to make slightly less whisky, etc. You have to grow demand, grow value through quality rather than through quantity. And so it is a bit of an experiment in that respect. There’s certainly something a little bit utopian about it, which I’m sure a lot of people will potentially scoff or laugh at or be dubious about, which is all fine but we’ve started and we are determined to do it.

It is a bit scary but I’ve no interest in doing any other kind of distillery. If I’m going to make whiskey, this is the whiskey we want to make.

KM: So is this a bit of a noble experiment then? What do you think will be your main issues once you have product to release?

AM: So long as you have distribution, there are fans of those whiskeys who will buy it. And you will get some advantage from the fact that there will be a scarcity issue. You know, there won’t be lots of other brands doing this. We won’t have a lot of product on the market, so people will pay whatever the going rate is to get it. It’s almost, but not quite like the Springbank thing. Springbank sells everything they put out. If you can do that and you have priced it accordingly, people are interested.

KM: What do you think will be the hardest part of this going forward?

(Credit: Kurt Maitland)

AM: Price will be one of the trickiest things we’ve got to balance, because we’ll have to crunch the numbers and look at what we need to charge to make a margin that sustains the business. We want to be able to make some meaningful profit for ourselves and our shareholders. This is our life’s work, we’ve got families, and this project is going to be hard to pull off. There are motivational reasons for wanting to be critically successful with our quality, but we want to be commercially successful as well.

The tension will be between what do we need to charge? What can we charge? What’s fair, what’s realistic, what is something which people are going to look at and know they are getting value and then what’s greedy, what strays into the territory of being ridiculous and starts to completely undo all the hard work you’ve put into the liquid.

That’s the tension, that’s the balance that we’ll have to work through.

KM: What are some of the other challenges?

AM: I think that we do live in a whisky ecosystem around the world now. It’s not the Age of Innocence anymore. People are much more switched on, much more educated, much more clued up. There is an audience there for the sort of product we’re going to make, and we know how to communicate with it.

One of the benefits we’ve got is we all come from different elements of the whiskey industry in different parts of the world. We’ve got quite a lot of pooled experience, lots of contacts, quite a few people who that have invested in the distillery are also people that do distribution or importing into other markets. So I think there’ll be a lot of goodwill and a lot of support for the product when the time comes, and provided we can do our job right.

We, you know, like any distillery, you can usually sell your first release and maybe even your second, but selling your second year through to your 10th and beyond up to into age statement/ larger batch products, that’s where the real challenge is, and people do lose interest.

KM: Is there a particular part of your whisky experience that you are pulling from when you think about this?

AM: I learned this with Decadent Drinks that when you’re the new kid on the block, everyone wants to buy. Everyone’s interested. But as time goes on, interest shifts. You’re no longer the trendy new thing. Something even shinier comes along and grabs that attention and that interest away.

So how do you build something which is going to be something people want to revisit and open and drink, and how do you price it in a way which meets your financial needs and desires as a business, while also still making it accessible enough for enough people to have that experience? I don’t just want this to be a shelf filler or a box ticker for you know, the purely collectible or investment types. I’m sure there will be an element of that, but the underlying fundamental thing that sustains Kythe is going to have to be the quality and drinkability of the liquid, and the desire for people to open a bottle and drink it.

That is what has driven the long term interest in old and rare whiskeys. And it has to be what drives interest in Kythe as a new single malt in the market.

KM: On some level, you have an advantage as your audience are people who are familiar with getting auction bottles and the prices those incur. They’re used to paying more for what you want to give them.

If you can create your ideal whiskies, the range in which you can charge for a bottle is basically that it needs to be cheaper than getting a 10-year-old from the 60s from an auction. If that is the case, there is a lot of give what you can charge and there’s definitely a market for that,

AM: Absolutely. I imagine our first calendar year of production will be somewhere between 50,000 and 60,000 liters of pure alcohol, which is tiny. We know who our audience is. This is a project and a concept which is pitched at people who are geeks, hardcore whisky educated, know their stuff, know their tastes, know what they like, but equally, in that headspace, know the value of these things, and are willing to spend a bit more to get them.

There’s a reason for being deliberately on the small side, at least to begin with, we can probably expand a little bit in that we’ve got space for two extra washbacks to go in if we want to, which means we could expand our output slightly without dropping our fermentation time, or, you know, putting any extra strains on the quality aspects of the process. But that’s for further down the line,

It’s also possible that our yield may be slightly higher than we have calculated. We’ve modeled our output on an assumption of 310 leads of pure alcohol per ton of malted barley. And that is, really conservative. That’s insane compared to most big, serious commercial distilleries producing malt whiskey. We could still end up getting around 360, so if we’re above 310 we’ll do pretty good.

But it still doesn’t matter. We’re not getting away from the fact that we are a small operation, small output, product, very high quality, hopefully, and within that, that leads to a certain audience, a certain market, and hopefully gives us a certain resilience as well.

KM: It seems there might be a bit of a rough patch coming in the industry, so how have you planned for what might happen in the market?

AM: There are all these stories at the moment and people talking quite fatalistically about the future of the whiskey market. And I think there’s truth in that. If I were making, you know, mass market brands, blended Scotch whiskey brands, I would be a bit concerned about long-term sales. What do you do about all the various forces that seem to be aligning against you? You know, economic, social, cultural, etc.

But within that there’s still a lot of enthusiasm, and I think there always will be for beautiful, high-quality, carefully made, well-crafted spirits. The world of spirits can be many things at the same time. And there’s nothing about at the moment that gives me too much concern about what we are trying to do. I think our project is the right thing at the right time.

KM: So when you guys were planning out the distillery and figuring out how you wanted to make your whiskey, what did you research? Were you dragging up old records from distillers or old articles from industry digests?

AM: I think it’s a combination of many things. It’s reading quite widely. It’s looking at old distillery data, so production sheets, production logs. It was also talking to older distillery workers that were still around and lived and worked and did these things.

They were not necessarily, you senior people that might have some element of loyalty to the company line or anything. There’s a guy that just told you how it was, as well as tasting extensively, you know, tasting things in the glass, which are kind of self-evidently different. I’m trying to sort of work backwards from that.

And then lately, it’s also things like this big James Eadie books that came out (The Distillation of Whisky and the Distilleries of Great Britain and Ireland – 1922 to 1929), which contain many useful insights,

KM: So is there an era you are trying to focus on flavor-wise?

AM: I think an era we are really interested is the pre-Second World War era, where I think you really get into true old styles of production, which is almost Victorian era production. And you have post-Second World War 60s, so sort of late 40s through to late 60s,

After that you have a big like transition that really ramps up in the industry from sort of ’70s onwards.

For us, it’s a combination of many things, different sources, different materials, trying to read, trying to talk extensively to different people, talk through the ideas with contemporary people in production and scientists and trying to get them to kind of stress test those concepts and those ideas.

And you know, after all that we have this hypothesis. We have what we think is a fairly good idea about how to get a distillate that has all the old style characteristics. The properties that will develop into waxiness, tropical fruit, the kind of characteristics that we love, something that will, you know, pair well with a more active sherry cask or a pretty plain refill hogshead. And the acid test is just going to come in finding out how long it’s going to take us to actually get there. You know, at what point do we actually know that we’ve achieved that? That’s going to be the thing where we’re pretty confident that we have a route through to that destination with the kit that we’ve put together and engineered and is currently being prepared on site. But it’s just at what point do you recognize that you’re on the right track with the distillate.

KM: What have you been able to do to test your theories so far?

AM: That’s where we’re a little less certain. Because with distillate,so much of it is precursor, so much about it is kind of embryonic, and it needs that time in cask to come out of its shell.

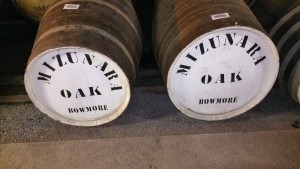

Thankfully, some of the most instructive things we tasted were old, very young cask samples of old style whiskeys. Like very old Longmore and very old Bowmore from the late 50s, early 60s. These cask samples were like four and six years old and they already had this very familiar sort of tropical fruit character, even at that very young age, from very simple wood.

So I think it does show you that these characteristics can appear quite early on. So that gave us a little bit of confidence, and also the fact that so many distilleries throughout Scotland, certainly, as you know, from the 60s and earlier decades, were producing what we would term, you know, classical, old style malt whiskey. They were making a whiskey of a style that we would be very happy to produce ourselves. And they all went about it in subtly different ways. That’s recorded in written evidence. You can go back and look at the, you know, whether it’s individual pamphlets from certain companies, whether it’s specific brochures about a certain distillery, whether it’s journalistic data of the kind of James Eadie or Alfred Barnard, early written whiskey blogging, essentially, all these things reveal in fact, there were subtle differences from each distillery and yet almost all of them that I’ve tasted arrived at something beautiful and distinct and very much in that old style tradition. So there’s more than one way to reach that destination, and I think the fact that there were so many idiosyncratic, subtle variations that were site specific, distillery specific only strengthens, you know, our view and reason for doing this, which is that Scotch whiskey used to be a less homogenized product, and there used to be more individuality coming out of the various distilleries in terms of the specific character of their makes.

KM: What “old style” methods are you looking to use at Kythe?

AM: We knew we wanted to do slow, clear wort mashing. We knew we wanted to do pretty long fermentation times using Brewer’s yeast. And we knew we wanted to do direct firing and worm tubs. Various subtle variations that can be done within that, but within that kind of core, broad brushstroke description of old style production, we knew what we wanted, and there was nothing that we came up against that persuaded us otherwise.

We were very open minded to be persuaded otherwise. Because, you know, one thing you can’t do is get trapped inside some kind of absolute dogma. I know there’s probably some critics of mine that would say that I am but, you know, I try to be very open to changing my mind about things.

So for example, you know, we’ve built ourselves capacity to do a two-week fermentation standard if we need it. But if the Spirit is telling us that we’re getting better results with half that time than so be it. The point is we build in a standard so that we’ve got the maximum amount of flexibility to do that if we need to.

KM: Well, that’s the thing when you’re building out a new distillery. Trying to build in the capabilities, like the max capability you think you need, because it’s so hard and so expensive to go and change it out if you don’t have it there. I get the sense that most would rather have more capacity than you ever end up using than less, and having to, like, rip it all out and have to do it again

AM: I’ve no doubt that down the line, there’ll be things that we will realize and look back and think, “Oh, if we’d known this then, or if we thought about this at the start, we might have done it differently.”

But then, by the same token, you know, what we’re doing is, you know, it’s kind of industrial, and it’s finding a recipe and cleaving to that recipe. But it’s also creative. And I do think creativity sometimes flourishes with a little bit of confinement and a little bit of adversity. So, you know, I’m confident in the design of our stills and that the cumulative effect of our setup is going to give us the room we need to create what we want to create.

And if there is a little bit of challenge within that or a little bit of adversity within that system, then I view that as an opportunity to be creative and make it work for us.

Let’s make it part of the distillery character. The kind of collective prime directive for Johnny, Aaron, and myself, is that people will be able to pour a glass of Kythe and say, “Ah, that is Kythe new make.” And I think that if we can get to that, get to having a whisky that distinctive, that would be really, really something.