What Is Whisky And How Is It Made?

Whisky servings are an important part of many celebrations. It is a highly-valued drink, loved by many across the globe. Much like other alcoholic beverages such as vodka and gin, whisky has a high alcohol concentration, which tends to make it a more “fancy” drink compared to the likes of beer and is a very popular cocktail ingredient.

Whisky has its fame, with many movies associating the drink with opulence. An amber-colored drink poured into a glass with a pair of big ol’ ice cubes is a common sight in various Hollywood movies.

And, outside of films, I wouldn’t be surprised if many people spend a nice summer weekend out on the lawn chair with an iced glass of whiskey reading a book, or magazine, playing for a casino jackpot, or watching some TV.

So, what is whisky? Why is it popular? And how is made? This article will address these questions and more.

What is whisky?

Whisky is a distilled spirit produced through a process of grain fermentation. The grain can either be wheat, rye, corn, or barley.

Whisky’s alcohol content is increased through distillation. And most whiskies are allowed to age in wooden casks before bottling in branded bottles.

Whisky varies in price and flavor depending on the place of origin, the blending process, the type of grain used, and the aging process.

For instance, brandy comes from distilling wine, vodka is distilled from grain although not aged, rum is made from distilled molasses or sugarcane juice, and gin comes from distilled grain but flavored with other ingredients.

Did you know that whisky is a Gaelic word “uisce beatha,” meaning “water of life?” This could be because water is an important ingredient when making whisky.

Before discussing how whisky is made, let’s highlight its ingredients.

What makes whisky?

Few ingredients go into making whisky, with the emphasis laid on the process more than the ingredients. Nevertheless, here is what you need to make whisky.

Grain mash: Making alcohol requires agricultural products that will be fermented. You can use one grain or mix several grains, including rye, corn, barley, and wheat. The type of grain used determines the whisky’s flavor and designation. For example, rye whisky has 51% rye, while Kentucky bourbon is made of 51% corn.

Water: Water is essential in regulating whisky’s alcohol content. Whisky makers often add water to the product after distillation to achieve the required alcohol percentage.

Some manufacturers even highlight their water sources, arguing that water sources significantly dictate whisky’s flavor. However, other experts argue that type of water does not contribute to flavor, and that water is only needed to change alcohol percentage.

Yeast: Yeast bacteria are needed to convert grain sugars into alcohol.

Optional additives: Today, many whisky brands add different additives to differentiate their products. These additives could include spices, botanicals, color, or flavorings. They are often added during aging or distillation to give the whisky its unique appearance or distinctive character.

Time: You are probably wondering how time can be an ingredient. Before bottling, you need time to age your whisky in wooden casks or barrels. The aging process gives the whisky unique flavors and colors.

In some countries, whisky is aged for at least two years, but some take 10 to 12 years. The longer the aging period, the classier and costlier the whisky.

How is whisky made?

Besides the ingredients, the whisky-making process takes five steps. Let’s take a look at these steps.

Malting the grain

Apart from barley, all grains used to make alcohol must be ground in a gristmill into a meal. The distillers will then pour water into the meal and cook it for some time to break down the cellulose walls having starch granules.

Barley which will be used in the mashing process undergoes a different treatment. You will soak it in water to saturation point. You will spread the soaked barley and sprinkle it with water for at least three weeks until it starts to sprout.

Sprouting produces the enzyme amylase, which converts barley into sugars. Hot air from a kiln is then used to dry the barley. The malted barley is ground before mixing with water to form a meal.

Mashing

This process involves mixing malted barley with cooked grain and warm water. Enzyme amylase will then convert the grain starch into sugars. You will continue squashing the mixture for several hours until you attain a thick sugar-rich liquid called mash.

Fermenting

You will allow the mash to cool down and transfer it into large fermentation vessels or tanks to start the fermentation process. Yeast is then added to the mixture to ferment the sugar into alcohol.

Generally, fermentation takes 48 hours, but some distillers looking for a unique product taste will allow the longer fermentation periods. The resulting liquid from fermentation often has between 5-10% ABV (alcohol content) and can be turned into a beer through the brewing process. Whiskey on the other hand requires the distillation of the liquid.

Distilling

Distillation is probably the most critical process when making whisky. If you want scotch whisky, you will likely use traditional copper pot stills.

However, modern distilleries employ continuous stills and cylindrical columns fitted with perforated plates. How do they work?

Steam is channeled into the continuous still from below while the beer is poured from the top. The beer is distilled as it drips through the plates and condenses into liquid alcohol.

The first distillation process is not enough since it generates unsuitable low wine. The distilled liquid will undergo a similar process two or more times, depending on the level of alcohol concentration you are looking for.

The distilling temperature determines the alcohol, water, and congeners’ proportion in the whisky. Whisky with 95% alcohol content is flavorless since it does not have congeners.

Distillers should find the right balance of congeners because a lot of them will make your whisky taste bad. But how can you remove congeners from your product?

Most distillers boil the whiskey to remove the bad-tasting congeners. Alternatively, you can pour them off if they are light and floating.

Expensive wines like Tennessee whiskey are passed through charcoal. The charcoal should have been burned in sugar maples and act like filters to remove congeners, thus giving the whiskey a smooth taste.

Aging

After distillation, water is added to reduce its alcohol content to 50-65%, depending on the country of origin. Some whiskies aged in warmer and drier environments like the American whiskey will likely increase their alcohol content during the aging process because the heat will evaporate the water.

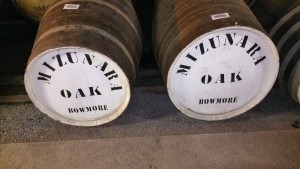

The aging process occurs in the wooden barrels made from charged white oak. White oak is preferred because they leak liquid and allow water to move in and out of the wood pores, thus adding flavor to the drink.

Whisky can take 2-4 years to mature, but most distillers take between 10 and 15 years. The longer the maturity period, the more expensive it is.

Aged whisky can then be bottled for distribution to various vendors for consumption.

Final words

Whisky takes an elaborate process and years to make. This explains its high prices when compared to other alcoholic beverages. It undergoes distillation and flavoring to give it color and a unique taste. Now you know how whisky is made and why some people only prefer it as a refreshment drink.