By Richard Thomas

(Credit: Paul Caldwell)

One of the problems confronting early entrants into the American micro-distilling boom was finding someone to build a copper still to suit their needs. In just one example, the Barrel House Distillery in Lexington, Kentucky told me that when they opened in 2008, they had to go to the Hoga Company in Portugal to find what they wanted, and this was with the famed Vendome Copper and Brass Works just an hour’s drive away in Louisville.

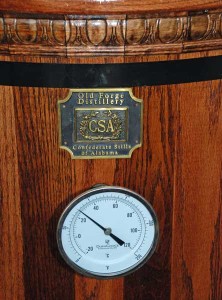

Yet just as the demand for whiskey and craft products has spurred the micro-distillery boom, so it has also spurred the growth of enterprises in the business of providing those small copper stills that are the cornerstone of that boom, enterprises like Confederate Stills of Alabama.

From Nuclear Power to Distillation

Paul Caldwell started Confederate Stills in 2012, with an eye on his retirement from the nuclear power industry the following year. As strange as it may sound, the 35 years Caldwell spent working on nuclear reactors for the U.S. Navy and Farley Nuclear Power Plant served him well in building his first still, because as he says it gave him a foundation in “process systems, heat transfer, fluid flow, etc.”

(Credit: Paul Caldwell)

After seeing the Discovery Channel program Moonshiners, Caldwell decided to build his own still. After doing so and making a few production runs, Caldwell wanted a cypress fermentation tank to go with it, and built that too. Eventually his wife grew tired of having the smelly fire hazard of a whiskey-making facility set up in their garage, so Caldwell sold the kit to a start-up in Colorado.

Stillworks in Alabama

That sale started him on the path to opening his own business. Caldwell initially provided stills to another company, but eventually he set up his own enterprise, naming it Confederate Stills in honor of his great grandfather, Henry Jackson Davis. Caldwell’s Confederate ancestor served in the 34th Alabama Infantry, a veteran regiment that fought at Stones River, Chickamauga, Chattanooga, the Atlanta Campaign, and Nashville.

(Credit: Paul Caldwell)

Confederate Stills provides two principal products for distillers: copper stills and cypress fermentation vats. While the copper adds a luster to a distillery, in my mind it is the latter in particular that offers a touch of class to a distillery. While some major distilleries use stainless steel for fermentation, and I’ve seen plenty of micros using plastic, nothing is quite the same as seeing a big cypress vat.

For the copper stills, Caldwell outsources the major copper work for his 100 to 250 gallon stills to a Virginia coppersmith. “Then I insulate, and do the woodwork, build the stands, and do the columns or pot heads/ thumpers / worms” explains Caldwell. His bigger still projects go to an industrial tank company. The 75 to 1000 gallon cypress tanks are built on-site, and most of the materials used by Confederate Stills comes from the U.S. “I don’t want to be another importer of cheap Chinese products” says Caldwell.

The Copper and Cypress Business

“My goal is to be able to provide a high quality, US made product for those that want to start up a distillery at an affordable price” says Caldwell. “[…] My products also give the advantage of looking unique, when people visit the distilleries with my stills/tanks they see something unexpected. A functional still that’s also a master woodworkers art.”

(Credit: Paul Caldwell)

Those interesting still designs have made their way into a number of distilling projects around the country. One of the stills at Hatfield & McCoy Moonshine in West Virginia is a Confederate Still, with another in the works; two distilling projects in Pigeon Forge, Tennessee will be using Caldwell’s copper when they open; and a still for Three Brothers Distillery in Virginia is under construction. That doesn’t include the various non-whiskey projects Confederate Stills has furnished equipment for.

That good work has not gone unnoticed. Now retired from the nuclear power industry and working on his still- and tank-building business full-time, Caldwell has been invited to speak at the April conference of the American Distillers Institute.

Too bad about the racist connotations of the name. Total turnoff to a large percentage of potential buyers.

Not really Frank. It is about QUALITY versus emotions. Get over it.

Great woodwork!

Do you have a list of Still manufacturers in the US. If not, do you know where I could find one?

Knowing Paul, anything he works on will be top quality, look good, and work well.

I purchased a couple of Paul’s fermenters “used” from another distillery this year. Upon pulling them apart for rebuilding, we were extremely disappointed to see that they we put together with nails and silicone. I personally build some similar fermenters for my distillery out of Douglass Fir and White Oak (easier to find locally). We use beeswax and good steel hoops for pressure. I figured that this was the industry standard but not here. My problem with the nails should be obvious. The nails we found were rusty and deteriorated even sunken in the wood. The silicone, although likely food grade, is probably cheaper than beeswax, but pretty nasty to think that this stuff could potentially come off the fermenter and be mixed and heated in the still with the mash. I would not recommend these if you run a DSP.

Paul does a fine job. He has provided several of my projects with tanks. And I have ran his stills and all are top notch. And whomever made the snide racist comment. Quit believing everything you read and educate yourself . Before you go making such comments.